Something to Think about Next Time You Print with Samsung Printers

At the CeBIT 2014, Samsung introduced its new line of NFC-enabled Printers and Samsung Cloud Print™ tailored for SMBs. In the rapidly evolving world of technology, it is not a surprise to see Samsung’s printing technology stepping up its game. However, Samsung clearly understands that, in the end, printers need to print good quality images.

Talking about quality images, here is something you already know. Your printer uses 4 tones- Cyan, Magenta, Yellow, and Key (black) – and not surprisingly, this is called the CMYK color model. Every color that your printer produces is made with these four colors. For example, to print ‘red’, your printer needs to mix an exact amount of magenta and yellow with the precise pressure on a dot to make the common color called red. So imagine the kind of work your printer needs to do when you command it to print a picture of you at the Holi festival in India.

How Our Expectations for Printers have changed

Back in the day, what people cared about the most in a printer was that it printed ‘text’ correctly and fast. However, nowadays, people are expecting printers to print in high-resolution, just like the images from any of their devices, such as computer, tablets or smartphones. In case of businesses, they not only have to print out documents for themselves, but also for official use, such as logos; and colors for logos need to be precise. The final image is extremely important, especially for businesses.

Due to the factors like advancement in device technology and an increase in business demands for printers, their accuracy of the image has become extremely important. As a result, the process of developing printers, especially in terms of imaging, has become much more scientific and complicated.

There are very few companies in the world that manufacture printers and, obviously, they always try to make sure every image people desire can be printed correctly.

How Printers Print

Let’s think about how printers print images. For easier understanding let’s compare imaging on TVs and printers for example. On a TV, each pixel is assigned a color on a still frame of a TV display. However, as printers print, the paper is sliding out while the printing is happening. The basic process of printing could be described in three basic steps.

First, the toner finds the assigned dot correctly, marks the color on that dot, then presses the color on the paper like it is ironing a shirt. Generally, laser printers are able to print about 600 dpi (dots per inch). However, while all these steps are happening instantly, remember that the printer is also printing on a moving object. To make the correct color, all the dots need to be precisely located with the right amount of toner.

In this aspect, the process of printer imaging could be considered a very complex and complicated process. We shouldn’t disregard the fact that there are many more external factors that could negatively affect the quality of printer imaging, such as dust.

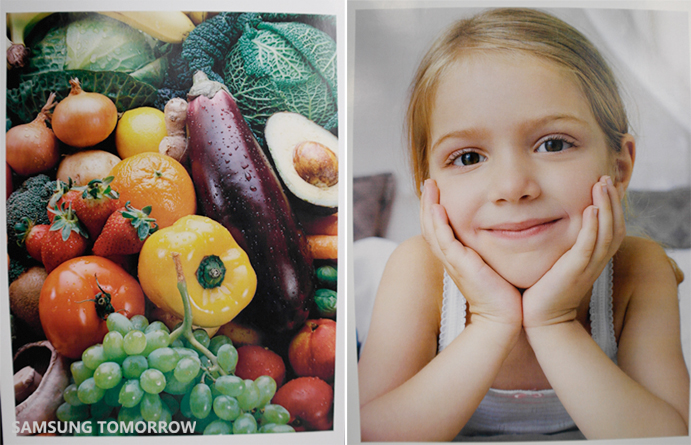

▲ Sample images printed with Samsung printers

Goal of Printer Imaging

Samsung has two goals when it comes to printer imaging. The highest priority when it comes to printing is that printing incorrectly never occurs. For example, when the printer doesn’t print the right color on the right spot or doesn’t print at all, it critically damages user’s experience. Every image needs to come out correctly 100% of the time and this is our first goal.

Another goal that should be achieved simultaneously is ‘emotional imaging’. An example of an emotional imaging would be printing an image of a sky like the actual sky we see in real life or even more real. Bringing a printed image where people can feel and relate to it emotionally is what Samsung calls emotional imaging. Consequently, to achieve this, image and its colors need to be more than great.

Evaluating Imaging Quality

Obviously, Samsung has more than enough ways to ensure the quality of the Imaging of Samsung printers, since there are many divisions of Samsung involved in the Printer projects. For example, you will need the material and chemical divisions for the particles of the toner; the computer and electrical division for the printer to select the color assigned by the device correctly; and the mechanical engineering division for the printer to produce a consistent result.

However, what we want to talk about is the ‘Imaging quality evaluating’ of Samsung. Even if the printer is fully developed, if it fails the image evaluating, the printer will never go on the market until it passes; image evaluating is like the final round of the competition. In fact, Samsung does image evaluating from the beginning stage of the product development, just to make sure.

Imaging quality evaluating is an important process, because as the quality of image improves, it gets more difficult to analyze or evaluate the color. There are times when certain colors need to be modified in the qualifying stage; for example, a blue to be bluer. Can you imagine being an evaluator and asking the developers to make blue bluer? It won’t really help them.

In the end an image is experienced by people, therefore, it is important for people to evaluate a color. However, as you can imagine, if the image is only evaluated by humans, evaluation will vary and be inconsistent; human aren’t computers. How would a computer evaluate colors anyway?

The IMQS

Samsung has this thing called IMQS (Intelligent Manufacturing Quality System). IMQS can recognize color the way human eyes recognize it, which it translates and assigns a code to each color. A computer can assign a number to every color that a printer can produce. Since IMQS is able to recognize and assign each color a number/code, it neutralizes the difference in color perspective among people. Before this system, people have been evaluating colors just with their eyes, which could result in inconsistent evaluations if solely depended upon. IMQS, obviously, saves a lot of time and effort for everyone.

The IMQS implementation allows the colors of each printer to be evaluated right after it is developed. It could also qualify each product immediately after it has been manufactured. Since printers are mass produced and more colors are being implemented, there could be some unexpected defects. IMQS minimizes this by evaluating all the colors for each printer and if there is a defect, people at Samsung can easily figure out a way to fix it since all the colors are saved as data in the computer. Therefore, it is able to make sure all printers are consistent in terms of quality. Less defective printers equals more happy people.

IMQS being able to computerize colors as data means that data could be accumulated and monitored, which Samsung can utilize to make improvements. Therefore, Samsung has data for each printer that is out in the market. One thing Samsung is trying to do with this fact is that when there is a complaint by a customer, they track the printer by the serial number and analyze the issue to solve it.

This would be especially great for B2B customers of Samsung. Actually, with the IMQS Samsung is trying to implement a service for B2Bs where a service specialist can analyze the color correctly and fix problems on site. For B2B, Samsung provides a printer specialist who installs and maintains the printers in the business offices. This will be a significant improvement from the conventional way of maintenance service since it will greatly reduce the time needed to solve issues.

We’ve went over how imaging in printers work and how Samsung evaluates its imaging quality. It must be emphasized that the advanced technology of IMQS is not the only way Samsung evaluates colors for its printers. Samsung recognizes that people are the one who experience the image, so people need to evaluate the image, so they can also see how the image feels… to the human eye. Therefore, imaging quality evaluators are at the end line of judging the emotion of the image. Stay tuned for more information on what it is like to be one of the top image evaluators at Samsung.

Products > More Products

For any issues related to customer service, please go to

Customer Support page for assistance.

For media inquiries, please click Media Contact to move to the form.